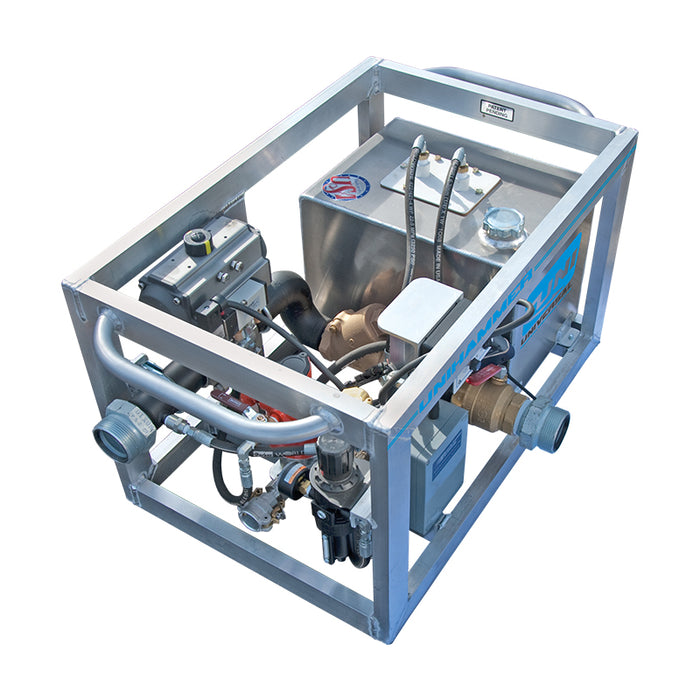

UNIHammer Directional Drilling Air Hammer

Why drill with air?

- Little to no water needed

- No refilling water when drilling tough ground (300 gallons will typically last all day, even in rock, on large drills)

- No moving the bore around because of ground conditions. Soft clay to solid rock can be handled with one head

- Less mess that mud system

- If the ground or rock is tough, simply go bigger air. UNIHAMMER can handle up to 500 psi for the extreme jobs

How much air?

- As small as a 400 cfm/200 psi to 1150 cfm/ 500 psi. Ground conditions and length determine your size needs

- The control unit has a built-in pump that supplies from 1/2 gallon per minute to 3.5 gallons per minute of fluid to aid in cutting removal and cooling the sonde. No need to run the pump on your drill

- A wireless remote control activates the supply valve at the control unit for your drilling air needs

- Sonde housing handles both DCI and SubSite sondes, up to 19” and wireline compatible

Versus the competition

- In Head to Head testing, the UNIHAMMER out produces the other air hammer systems on the market

- Specific Metal Compound is used to ensure longer bit life and housing life

- Designed to maximize airflow to provide downhole power, while saving compressor fuel costs by running smaller compressors

- Specifically designed to handle more water for cuttings removal and cooling

- Bit designed to grind up cuttings more efficiently and finer to help keep the hole clean

- Designed and tested for everyday use, not just rock boring, giving you a better return on your investment

- Sonde Housing has been verified by DCI to work with all DCI® sondes. Also compatible with all Subsite sondes.

4” Hammer

- Highest Striker Weight to generate power

- Runs on less air, 750 cfm / 350 psi compressor is ideal. This means smaller compressors and fewer fuel costs.

- Designed to run with large volumes of water to help flush hole, or to compensate for groundwater

- Oversized 5.5” head saves wear on the housing and provides better steering and longer life. Allows pullback of 4” pipe with no reamer.

3” Hammer

- Designed to run on 400 cfm / 200 psi compressor

- Small compressor options, allows a simple set up and low operating cost

- Can turn a small drill like the 7x11 into a rock drill or aide in tough ground conditions that are not quite rock

- Works all the way up to 24x40

- 4.5” cut allows pullback up to 3” diameter with no reamer